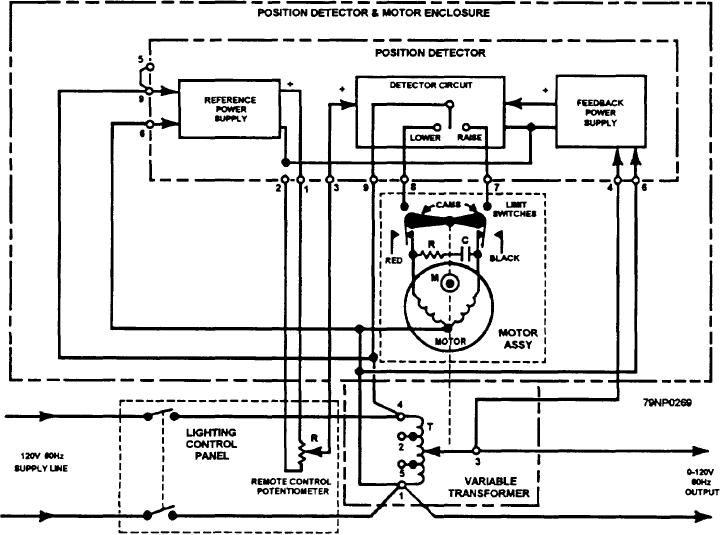

to the lights (fig. 12-28). The transformer wiper

until the feedback voltage equals the reference, and the

motor stops at a position corresponding to the desired

(secondary) is moved by the synchronous motor which

light intensity. Cam-operated limit switches open the

is controlled by the potentiometer in the lighting control

motor circuit and prevent the motor from driving the

panel. The detector circuit in the position detector

wiper on the transformer beyond the upper and lower

determines from the setting of the remote control

stops.

potentiometer whether the motor turns in a direction to

raise or lower the output voltage.

MAINTENANCE REQUIREMENTS

The reference power supply in the position detector

converts ac input voltage to dc, and the potentiometer in

The VLA system contains many electrical and

the control panel determines the magnitude of dc

electronic components which require both preventive

reference voltage sent to the detector circuit. The

and corrective maintenance. The components that we

feedback power supply in the position detector converts

have discussed in this chapter contain many motors,

the ac output voltage from the variable transformer to a

controllers, blowers, heaters, pressure switches, and

proportional dc voltage which is also sent to the detector

lighting fixtures that are exposed to weather. The

circuit.

electronic portions are solid state and are primarily on

The detector circuit consists of a comparator and

printed circuit boards. As an Electrician's Mate you can

solid state switches (TRIACS) which energize either the

realize some of the problems which will be encountered

clockwise (LOWER) or counterclockwise (RAISE)

both with electrical and electronic parts. It is of utmost

windings of the drive motor. The drive motor rotates

importance that you follow all PMS requirements

the wiper shaft on the transformer in the proper direction

carefully to keep all portions of this system operating

Figure 12-28.--Motor-driven remote variable transformer circuit diagram.

12-20