CHAPTER 14

ENGINEERING CASUALTY

CONTROL

CASUALTY PREVENTION

The operating efficiency of a ship depends largely

on the ability of the engineering department to continue

Casualty prevention is the most effective phase if

its services both during normal operations and during

casualty control. It concerns the quality of preventive

casualties. Casualty control is concerned with the

maintenance on machinery and systems as an effort

prevention, minimization, and correction of the effects

toward counteracting the effects of operational and

of operational and battle casualties. Casualties are used

battle casualties. Proper preventive maintenance

in this chapter as defined in Naval Ship's Technical

greatIy reduces casualties caused by material failures.

Manual, chapter 079, volume 2.

Continuous detailed inspection procedures are

necessary. These inspections are necessary to disclose

LEARNING OBJECTIVES

partially damaged parts that may fail at a critical time

Upon completion of this chapter, you should be able

and to eliminate the underlying conditions that cause

to do the following

them. Some conditions that can cause failures include

misadjustment, improper lubrication, and corrosion.

1. Recognize the purpose of casualty control

These conditions are detrimental to machinery and

training.

cause early failure.

2. Identify the purpose of the Engineering

Casualty prevention requires constant training.

Casualty Control Evaluation Team (ECCET).

Casualty control training must be a continuous

3. Recognize the purpose and identify the use of

step-by-step procedure. It should provide for study time

the Engineering Operational Sequencing

and refresher drills. Any realistic simulation of

System (EOSS).

casualties must be preceded by adequate preparation.

4. Identify the casualty control organization.

You must impress upon your watch sections the full

consequences of any error that may be made in handling

5. List the duties and responsibilities of personnel

within the casualty control organization.

real or simulated casualties.

6. Recognize some engineering casualties and

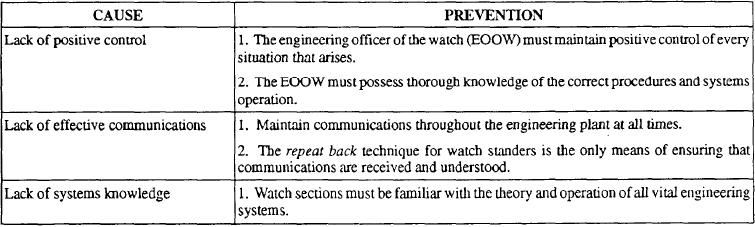

Most engineering plant casualties are caused by

identify the procedures for handling them.

lack of knowledge of correct procedures on the part of

watch station personnel. If a simple problem is allowed

This chapter contains a discussion about casualty

to continue, the ship may be disabled. The following

prevention, training, and restoration. These actions

chart contains the causes of ineffective casualty control

provide a ship with a well-rounded casualty control

program.

and their prevention:

14-1