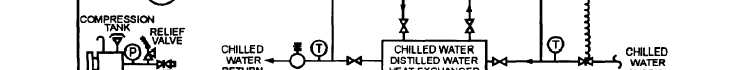

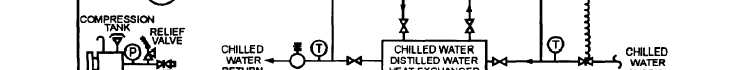

Figure 1-8.—Type III liquid cooling system.

taken from the firemain through a duplex strainer and a

flow regulator (orifice plate) to and through the heat

exchanger. It is then discharged overboard. The

connection to the firemain is permanent.

The ship’s fire pump, not shown in figure 1-7, is

used to pump seawater into the firemain. The fire pump

is similar in design to the previously mentioned seawater

circulating pump, except it has a much larger capacity.

Another means of getting seawater as a primary

coolant is by an emergency connection (figs. 1-6 and

1-7). This method is used if the normal seawater supply

is lost. The connection is usually by means of a 1-inch

fire hose. The emergency supply comes from an

alternate portion of the ship’s firemain or a portable

pump rigged by the ship’s damage control party. The

portable emergency hose is normally stored in the liquid

coolant machinery room.

Note: Seawater systems are referred to as

open-looped or one-pass because the seawater flows

through the system only once.

In figures 1-7 and 1-8, chilled water is taken from

the supply main of the air-conditioning, chilled-water

systems. The chilled water is used as a backup source

of cooling water for the primary cooling system shown

in figure 1-7, and as a normal and backup source in the

system shown in figure 1-8. The chilled water flows

through the tubes of the heat exchanger (chilled water

to distilled water), a flow regulator, and back to the

chilled-water system. A temperature regulating valve at

the inlet of the heat exchanger regulates the flow of

chilled water through the heat exchanger to maintain the

required water temperature in the secondary system

(distilled water).

The ship’s air-conditioning,

chilled-water circulating pump is used to pump the

chilled water through the heat exchanger. The

chilled- water system is a closed-loop water system

because the water is recirculated. It must be kept tight

and free from leaks to assure satisfactory operation.

SECONDARY COOLING SYSTEM

The secondary cooling system is designed to

transfer heat from the electronic equipment being

cooled to the primary cooling system. This system is

usually comprised of a distilled- water circulating pump,

a compression or gravity-feed expansion tank, the

1-6