the plunger is pulled so that the pinion engages with the

flywheel ring gear. The pull-in coil draws a

comparatively heavy current necessary to complete the

plunger movement. The holding coil aids the pull-in

coil. Continuation of the plunger movement closes the

switch contacts, permitting the starter motor to crank the

engine. As soon as the solenoid switch is closed (and

the pinion shifted), the pull-in coil is shorted by the

switch contacts in the starting-motor circuit so that only

the holding coil is energized to retain the plunger in the

operated position.

When the starter switch is released, the tension of

the return spring in the drive assembly actuates the

plunger to open the circuit to the starting motor.

BATTERY CHARGING SYSTEM

For you to maintain the battery in a fully charged

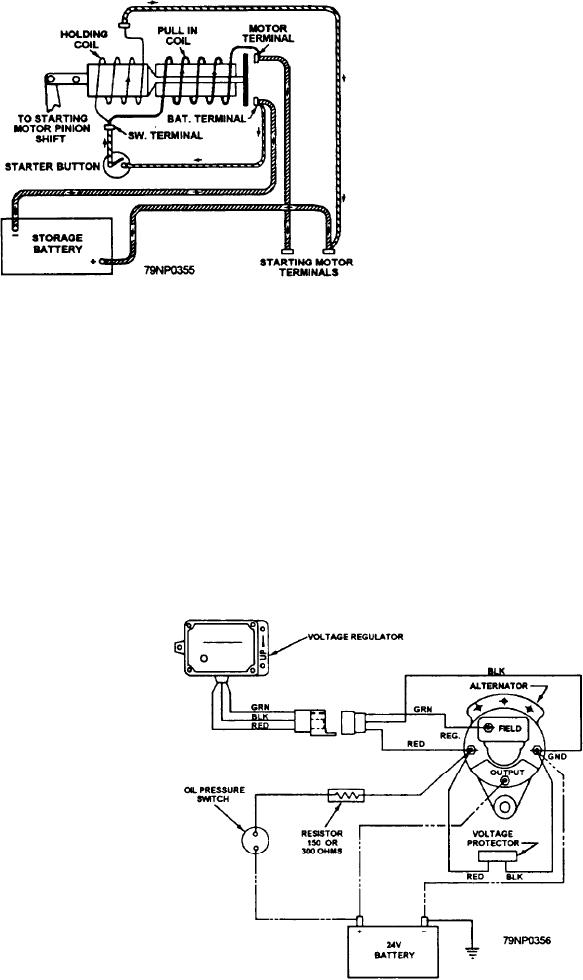

Figure 5-6.--Solenoid switch diagram.

condition, the discharge current must be balanced by a

charging current supplied from an external source, such

Control Circuitry

as a battery-charging alternator. If the discharge current

The solenoid shown in figures 5-5 and 5-6 is used

exceeds the charging current for an appreciable period,

on some starting motors equipped with overrunning

the battery will gradually lose its charge. It will not be

clutch drives to close the circuit to the starting motor and

able to supply the necessary current to the electrical

also to engage the pinion with the flywheel ring gear. It

system.

is mounted on the motor frame, as shown in figure 5-5,

A belt-driven alternator is used on small boats and

and has a pull-in coil and a holding coil provided with

service crafts. The alternator has several advantages

a spring-loaded plunger. A heavy contact disk is

over the dc generator. It is smaller in size, requires less

attached to one end of the plunger, and the other end is

maintenance, and supplies charging current at idling

connected by linkage to the shift lever. Both coils are

speed.

connected in series with a starter switch located on the

instrument panel (fig. 5-6). When the starter switch is

A typical alternator electrical system wiring

operated, both coils are energized (from the battery) and

diagram is shown in figure 5-7. The three-phase ac

Figure 5-7.--A typical alternator electrical system wiring diagram.

5-11