as required. Varying the current output reduces the

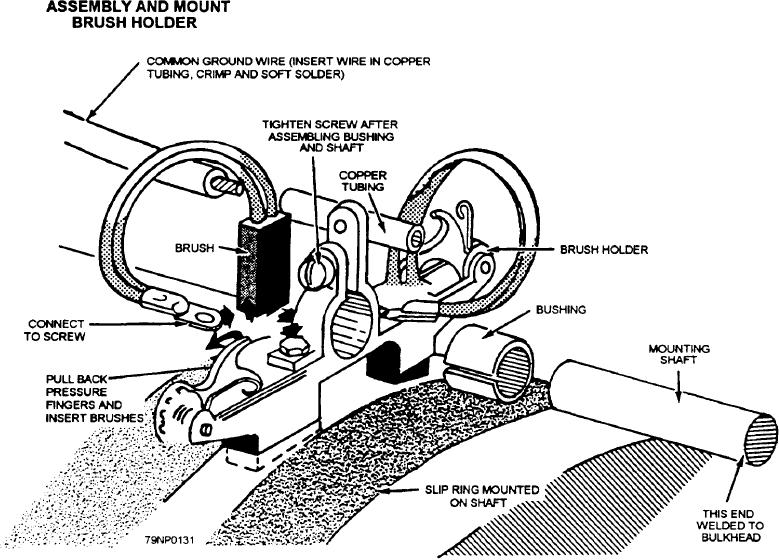

SHAFT GROUNDING ASSEMBLY.-- The shaft

grounding assembly (fig. 11-8) consists of a silver-alloy

potential difference between the hull potential and the

band, ring-fitted on the propeller shaft. The assembly

preset desired potential. Two reference electrodes are

is electrically bonded to the shaft and is usually located

installed for each controller--One is selected for the

in the shaft alley. Silver-graphite brushes ride on the

primary control, and the other serves as an auxiliary to

hard silver surface of the bands, electrically connecting

verify operation of the controlling cell and seines as a

the rotating propeller shaft to the hull. This assembly is

backup if failure of the primary cell occurs. Reference

necessary to permit the anode current that flows through

electrodes are generally located on each side of the hull,

the water to enter the propeller blades and return to the

about halfway between the anode sites. Reference

hull. A shaft grounding assembly is provided for each

electrodes are usually replaced approximate] y every 10

shaft. Ships of carrier size or larger are fitted with two

to 12 years.

brush assemblies on the silver-alloy ring.

STUFFING TUBE.-- Stufflng tubes are required

RUDDER GROUND.-- Rudders and Stabilizers

to insulate the electrical wires that pass through the hull

are grounded by brazing a braided, tinned-copper

to anodes or reference electrodes.

grounding strap at least 1 1/2 inches wide between the

Figure 11-8.--Shaft grounding assembly.

11-10