If the turbine has been standing idle for more than

After it has been determined that good oil is

available, the engineers should carry out the procedure

5 minutes without being spun, it is probable that the rotor

has been bowed temporarily. Upon restarting the

for placing a boiler on the line. The engineers should

turbine, vibration may be evident. If so, a brief slowing

then investigate and correct the cause of the trouble and

of the turbine will usually permit the rotor to straighten.

sound the tank to determine the quantity of oil in the

tank. If the oil is above the suction line, the fuel oil is

contaminated or the suction line is clogged. If the fuel

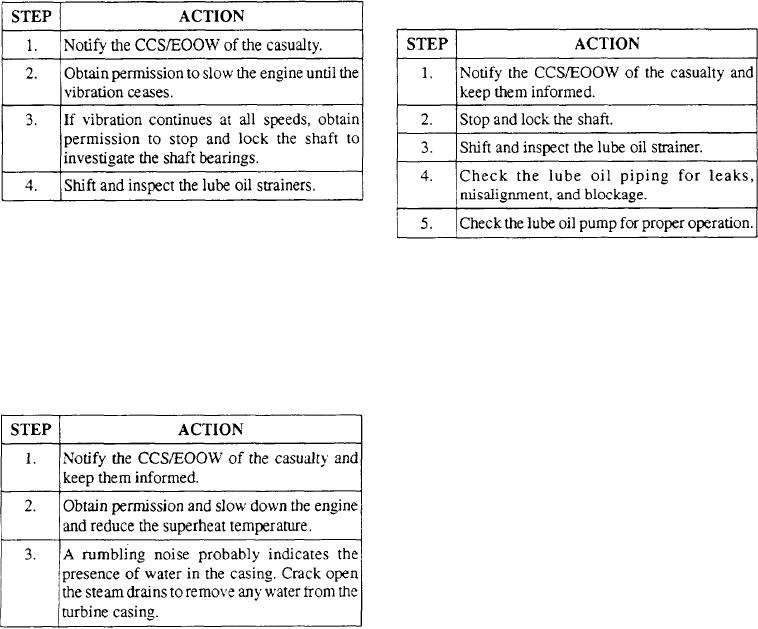

Loss of Lube Oil

oil contains water, the tanks should be sounded or tests

performed to find the source of the contamination.

All personnel should know that even a momentary

loss of lubricating oil can result in localized overheating

ENGINE ROOM CASUALTIES

and probable slight wiping of one or more bearings.

Such wiping may result in only a momentary rise in the

The operational engine room casualties that might

temperature of the lubricating oil discharged from the

occur include excessive vibration of a shaft, vibration of

bearing(s). Damage can be prevented or minimized by

a turbine, loss of lube oil, and many others.

stopping the shaft rotation and quickly restoring the

lubricating oil flow. Continued operation with wiped

Excessive Shaft Vibration

bearings can cause serious derangement to the shaft

packing, oil seals, and blading.

If a shaft develops excessive vibration, watch

personnel should take the following actions:

Upon indication of a loss of lube oil to the main

engine, the following actions should be taken:

The other engine should be speeded up to maintain

speed if the tactical situation requires. If the cause for

Loss of lubricating oil pressure may be caused by

the unusual noise is undetermined, inspect the propeller,

failure of the system itself. This includes failure of the

fairwaters (sleeves), and rope guards at the first

main lubricating oil pumps, failure of steam or electrical

opportunity.

power supply to the main lubricating oil pumps, or

damage to boilers, steam lines, or electrical equipment.

Turbine Vibration

Failure of component parts of the lube oil system

If a turbine begins to vibrate, the individuals on

may be caused by the presence of dirt, rags, or other

watch should take the following actions:

foreign matter. This is usually the result of improper

cleaning. Failure of the system may be caused by a

piping failure, a failure of the operating pump, or failure

of the standby pump to start. Standby pumps should be

maintained ready to start the moment the pressure drops

below a prescribed operating value. If automatic

starting devices are not available on steam-driven

pumps, the pumps should be lined up so that opening

the throttle is the only action required. Steam supply

lines to standby pumps should be drained continuously.

Where electrical pumps are installed, personnel should

be thoroughly familiar with alternate sources of power.

14-18