correct flow rate through the flowmeter. The high of a

flow rate can damage the cartridges. If the flow rate

cannot be increased to the proper rate with the inlet

supply valve fully open, you should check to ensure that

the outlet valve is fully open. The submicron filter is

used to remove small particles from the coolant flow

having a size greater than 0.5 micron. If the filter

becomes clogged, it also reduces the flow of coolant.

This necessitates a change of the filter cartridge or filter

sheet (membrane). To change the filter, the

demineralize valves must be properly positioned.

If the filter cartridge or membrane continually

becomes clogged (about one-half hour or less after

replacement), the usual cause in the distilled water

system is the presence of bacteriological impurities,

Bacteriological impurities introduced into the

secondary liquid cooling system using distilled water

may exist in the demineralize cartridges and/or the

whole secondary cooling system. If the bacteriological

impurities are in the whole secondary cooling system,

the growth rate in a warm water environment could be

of a magnitude that exceeds the capability of the

demineralize. You will have to determine the source

and magnitude of contamination. However, it should be

noted that bacteriological contamination in a secondary

cooling system that uses distilled water and ethylene

glycol is highly improbable.

Improper handling or storage of the cartridges could

cause the cartridge to be a source of contamination. You

should always store the cartridges in a cool, dry area.

Exposure to heat hastens the growth of any biological

contaminates that may have entered the cartridges. You

will encounter three different types of cartridges. The

first cartridge is the organic removal cartridge. It

contains granulated activated charcoal (carbon) that

removes large organic molecules and chlorine by

adsorption. It is always installed in the first exchanger

(if required) to prevent organic molecules from fouling

the remaining cartridges. The second cartridge is the

oxygen removal cartridge. It is composed of anion

resins that remove oxygen from the water by ion

exchange of sulfite ions to sulfate ions. By conducting

a standard oxygen test (or if the cooling system has an

oxygen analyzer installed), the quality of the outlet

water from the demineralize can be tested for oxygen

content so that you will know when to replace an oxygen

cartridge. When the oxygen cartridge is near

exhaustion, it will have a urine odor, which is given off

by the sulfate. The third cartridge is the mixed-bed

cartridge. It is filled with cation (positive charge) and

anion (negative charge) resins, which remove solids,

dissolved metals, and carbon dioxide. The charged

resins exchange ions with the contaminates, thereby

removing them and leaving pure deionized coolant. You

should replace the mixed-bed cartridge when the purity

meter indicates a low outlet purity.

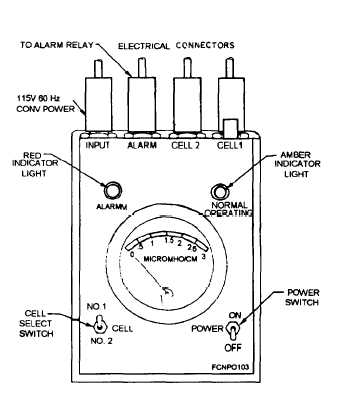

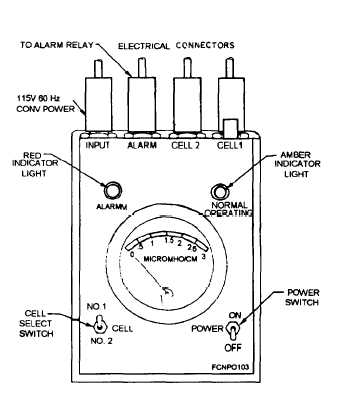

As indicated in figures 1-25 and 1-26, two

conductivity cells monitor the coolant through the

demineralize. The first cell measures the purity of the

coolant as it enters the demineralize. The second purity

cell is used to measure the purity of the coolant as it

leaves the demineralize. The conductivity cell consists

of two electrodes immersed in the coolant flow path.

The electrodes measure the conductivity of the coolant,

which varies with the amount of ionized salts dissolved

init. If the impurity content increases in the coolant, the

purity meter indicates higher conductance.

On some purity meters, the purity of the coolant is

displayed as resistivity. In this type of meter, an increase

in the impurity of the coolant causes the meter to

indicate a low resistivity. Conductance is the reciprocal

of resistance, and is measured in micromhos/cm.

Resistivity is measured in megohms/cm. You can

convert from conductivity to resistivity by taking the

reciprocal of conductivity. Similarly, the reciprocal of

resistivity is equal to the conductivity. A comparison of

both ways of measuring the purity of the coolant is

Figure 1-26.-Purity meter.

1-21