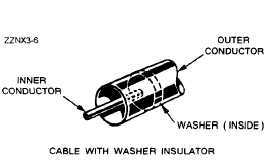

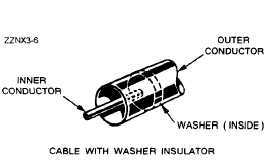

The rigid coaxial line consists of a central, insulated

wire (inner conductor) mounted inside a tubular outer

conductor. This line is shown in figure 3-13. In some

applications, the inner conductor is also tubular. The

inner conductor is insulated from the outer conductor

by insulating spacers or beads at regular intervals.

The spacers are made of Pyrex, polystyrene, or some

other material that has good insulating characteristics

and low dielectric losses at high frequencies.

Figure 3-13.—Air coaxial line.

The chief advantage of the rigid line is its ability

to minimize radiation losses. The electric and magnetic

fields in a two-wire parallel line extend into space for

relatively great distances and radiation losses occur.

However, in a coaxial line no electric or magnetic

fields extend outside of the outer conductor. The fields

are confined to the space between the two conductors,

resulting in a perfectly shielded coaxial line. Another

advantage is that interference from other lines is

reduced.

The rigid line has the following disadvantages:

(1) it is expensive to construct; (2) it must be kept

dry to prevent excessive leakage between the two

conductors; and (3) although high-frequency losses

are somewhat less than in previously mentioned lines,

they are still excessive enough to limit the practical

length of the line.

Leakage caused by the condensation of moisture

is prevented in some rigid line applications by the use

of an inert gas, such as nitrogen, helium, or argon.

It is pumped into the dielectric space of the line at

a pressure that can vary from 3 to 35 pounds per

square inch. The inert gas is used to dry the line when

it is first installed and pressure is maintained to ensure

that no moisture enters the line.

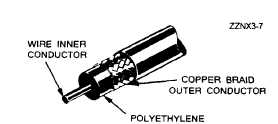

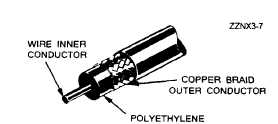

Flexible coaxial lines (fig. 3-14) are made with

an inner conductor that consists of flexible wire

insulated from the outer conductor by a solid,

continuous insulating material. The outer conductor

is made of metal braid, which gives the line flexibility.

Early attempts at gaining flexibility involved using

rubber insulators between the two conductors.

However, the rubber insulators caused excessive losses

at high frequencies.

Figure 3-14.—Flexible coaxial line.

Because of the high-frequency losses associated

with rubber insulators, polyethylene plastic was

developed to replace rubber and eliminate these losses.

Polyethylene plastic is a solid substance that remains

flexible over a wide range of temperatures. It is

unaffected by seawater, gasoline, oil, and most other

liquids that may be found aboard ship. The use of

polyethylene as an insulator results in greater

high-frequency losses than the use of air as an

insulator. However, these losses are still lower than

the losses associated with most other solid dielectric

materials.

This concludes our study of transmission lines.

The rest of this chapter will be an introduction into

the study of waveguides.

WAVEGUIDE THEORY

The two-wire transmission line used in conventional

circuits is inefficient for transferring electromagnetic

energy at microwave frequencies. At these frequencies,

energy escapes by radiation because the fields are not

confined in all directions, as illustrated in figure 3-15.

Coaxial lines are more efficient than two-wire lines

for transferring electromagnetic energy because the

fields are completely confined by the conductors, as

illustrated in figure 3-16. Waveguides are the most

3-8