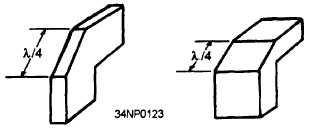

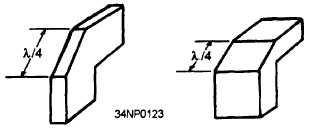

A sharp bend in either dimension may be used

if it meets certain requirements. Notice the two

45-degree bends in figure 3-50; the bends are 1/4l

apart. The reflections that occur at the 45-degree bends

cancel each other, leaving the fields as though no

reflections have occurred.

Figure 3-50.—Sharp bends.

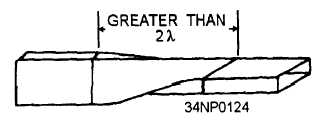

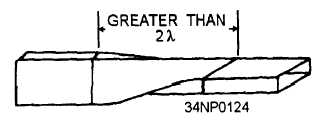

Sometimes the electromagnetic fields must be

rotated so that they are in the proper phase to match

the phase of the load. This may be accomplished by

twisting the waveguide as shown in figure 3-51. The

twist must be gradual and greater than

Figure 3-51.—Waveguide twist.

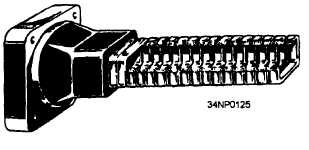

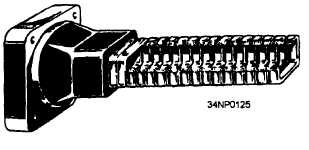

The flexible waveguide (fig. 3-52) allows special

bends, which some equipment applications might

require. It consists of a specially wound ribbon of

conductive material, the most commonly used is brass,

with the inner surface plated with chromium. Power

losses are greater in the flexible waveguide because

the inner surfaces are not perfectly smooth. Therefore,

it is only used in short sections where no other

reasonable solution is available.

Waveguide Joints

be

Since an entire waveguide system cannot possibly

molded into one piece, the waveguide must be

Figure 3-52.—Flexible waveguide.

constructed in sections and the sections connected with

joints. The three basic types of waveguide joints are

the PERMANENT, the SEMIPERMANENT, and the

ROTATING JOINTS. Since the permanent joint is

a factory-welded joint that requires no maintenance,

only the semipermanent and rotating joints will be

discussed.

Sections of waveguide must be taken apart for

maintenance and repair. A semipermanent joint, called

a CHOKE JOINT, is most commonly used for this

purpose. The choke joint provides good electromag-

netic continuity between the sections of the waveguide

with very little power loss.

A cross-sectional view of a choke joint is shown

in figure 3-53. The pressure gasket shown between

the two metal surfaces forms an airtight seal. Notice

in view B that the slot is exactly

from the “a”

wall of the waveguide. The slot is also

deep,

as shown in view A, and because it is shorted at point

1, a high impedance results at point 2. Point 3 is

from point 2. The high impedance at point 2 results

in a low impedance, or short, at point 3. This effect

creates a good electrical connection between the two

sections that permits energy to pass with very little

reflection or loss.

Whenever a stationary rectangular waveguide is

to be connected to a rotating antenna, a rotating joint

must be used. A circular waveguide is normally used

in a rotating joint. Rotating a rectangular waveguide

would cause field pattern distortion. The rotating

section of the joint, illustrated in figure 3-54, uses a

choke joint to complete the electrical connection with

the stationary section.

The circular waveguide is

designed so that it will operate in the TM0,1 mode.

3-23