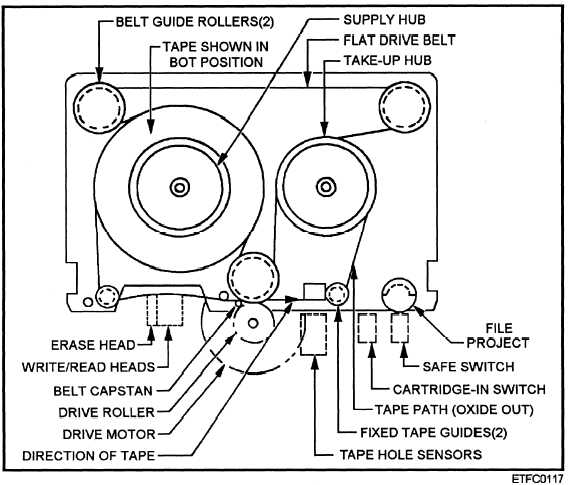

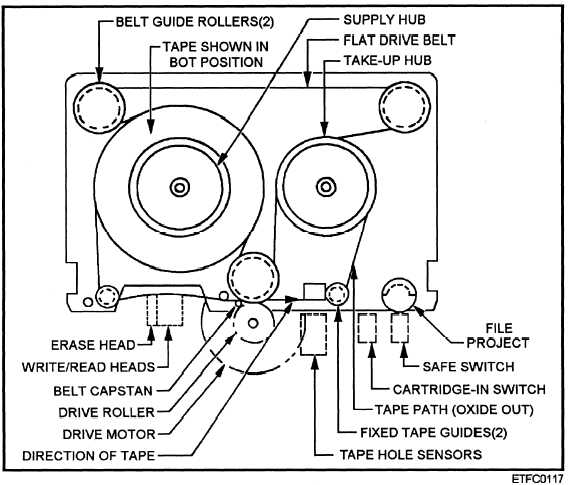

Figure 9-22.—A magnetic tape cartridge.

standard cartridge uses 600 feet of 1/4-inch tape.

Instead of reflective markers, holes punched in the tape

are used to indicate BOT/EOT.

The unit contains four read/write heads. Data may

be written on or read from four addressable tracks (0, 1,

2, or 3). Separate data maybe stored in each track, or

tracks may be used as a continuation of the previously

selected track. Data is stored serially one bit at a time

down the length of the track. Up to 60 megabytes of data

may be stored on one 600-foot cartridge.

Cartridge units are slower than standard tape drives,

but the cartridges are more rugged and easily

transported. In addition, the cartridge unit has less

moving parts than the standard tape drive, which

contributes to increased unit reliability and

,

maintainability.

TOPIC 3—MAINTENANCE

REQUIREMENTS

Preventive maintenance of magnetic tape devices

consists of performing mechanical and electrical

alignments and testing the tape units using several

different maintenance programs.

ALIGNMENT

Magnetic tape units require many mechanical and

electronic adjustments/alignments. Some of these

adjustments are required only during unit installation.

Others must be done when a faulty component or

assembly is removed and/or replaced. Still others are

needed because of normal equipment usage (wear and

tear).

Alignment checks or adjustments required on a

periodic basis are covered by the Planned Maintenance

System (PMS) Maintenance Index Page (MIP) and

Maintenance Requirement Cards (MRCs) that apply to

the unit you are maintaining.

You may find nonperiodic adjustment procedures

or technical specifications for periodic alignment

checks in the technical manual for the magnetic tape

device in your system.

9-19