In addition to lateral parity, many units use a

longitudinal parity check. A special check frame is

written after the last data frame of each record. This

frame, as shown in figure 9-10, contains the parity bits

for the sum of all the ONES written in each track. In

other words, each bit of the check frame is a parity bit

for that track of data. Longitudinal parity checks help

identify errors to the specific track or bit position on

tape.

TOPIC 2—MAGNETIC TAPE

DEVICES

Magnetic tape storage devices can be divided into

two functional areas, as shown in figure 9-12:

l Magnetic tape control or controller

l Tape transport

Now let’s take a look at a typical magnetic tape unit

and its associated tape transport. This unit is based on

the RD-358(V)/UYK Magnetic Tape Unit, but is a

compilation of several tape units. Specifications used

at your command and are intended only to help you get

a more detailed understanding of the electronic and

electromechanical nature of magnetic tape units.

The magnetic tape unit (MTU), shown in figure

9-13, provides auxiliary (secondary) data storage for

one or two computers (duplex operation). The tape unit

is used primarily for operational and maintenance

program loading for the combat direction system

(CDS). It is also used to record real-time data extracted

from the CDS, to copy maintenance and operational

program tapes, and to patch or modify maintenance and

operational program tapes.

This MTU can control up to four magnetic tape

transports (MTTs). Standard shipboard configurations

consist of two or four transport units. The MTTs use

0.5-inch, A-wound (oxide coating on the underside of

the tape as it is wound on the reel), polyester-based

magnetic tape wound on industry standard open reels.

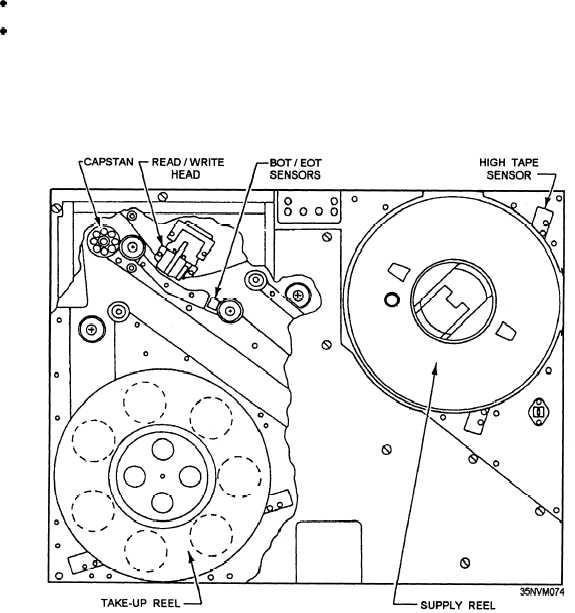

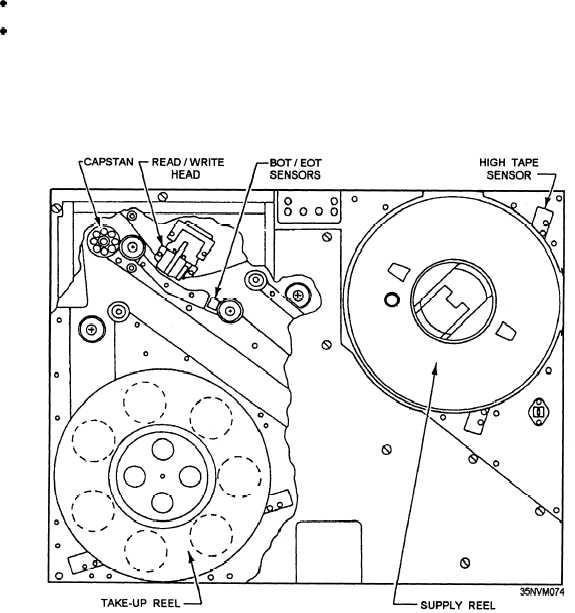

The MTTs are single-capstan, vacuum-column tape

may or may not be the same as the magnetic tape unit

drives as shown in figure 9-14.

Figure 9-14.—A magnetic tape transport.

9-11