(EOT). The length of tape between BOT and EOT is

refereed to as the usable recording surface or usable

storage area.

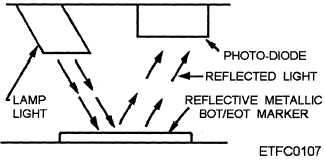

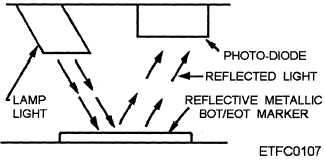

BOT/EOT markers are usually short strips of

reflective tape, as shown in figure 9-10. BOT is the

common starting point used in a system when writing

or searching for data on tape. Holes punched in the tape

or clear plastic inserts are used as markers in some units.

BOT/EOT markers are sensed by an arrangement of

lamps and photodiode sensors as shown in figure 9-11.

processing of large amounts of data. A data file is

nothing more than a group of records. Frames makeup

records, records make up files. Files are separated by

special identifying frames known as file marks,

end-of-file marks, or tape marks.

File marks are located at the end of each data file

on the tape. The first file starts after the start-of-tape

gap, as shown in figure 9-10. Notice the organization

of records and interrecord gaps within the file. The

second file starts after the first file mark. Following

files will each end in a file mark

Data Records on Tape

Parity Checks

One factor all magnetic tapes have in common is

that the tape must be moving at a predetermined speed

for data to be written on, or read from, the tape. In other

words, data cannot be written or read while the tape is

starting to move, stopping movement, or stopped.

This start/stop effect creates a blank spot on tape

until the tape is up to speed and can be written on. In

addition, these blank spots, or gaps, are used to separate

blocks of data or records on tape. Gaps separating

records are known as interrecord gaps. Refer to figure

9-10.

A record is nothing more than a group of contiguous

frames. The number of frames needed to store the

desired data determines the size of the record. The size

of a record may vary from a few frames to the entire

length of the usable recording surface. Record length

is a function of software (computer programs), not of

the magnetic tape device.

Data Files on Tape

Most magnetic tape devices provide for the

identification of files of data. Such identification

provides greater flexibility in the handling and

Figure 9-11.—A BOT/EOT sensor.

What are known as lateral parity and/or

longitudinal parity are common methods of ensuring

the accuracy of data recorded on tape. Lateral parity

checks use each frame’s parity bit. Longitudinal parity

checks use a special frame located at the end of each

record.

The two types of parity formats are odd parity and

even parity. Each of the data bits in a frame is written

as a ONE or a ZERO. Parity checks count the number

of binary ONES in the frame and store a ONE or ZERO

in the parity check bit to keep the total number of ONEs

in the frame odd or even.

As an example of odd parity, the six data bits to be

written as a frame (seven-track) consist of 010 011.

Three ONEs are in this frame. The total number of

ONES in the frame is already odd, so the parity bit will

be written as a ZERO. If the number of ONES in the

data bits were even (01 1 110), then the parity bit would

be written as a ONE to maintain odd parity. Odd parity

is commonly used with NRZI recording to distinguish

frames while reading. Since every frame will have at

least a single binary ONE, a flux change sensed on any

track indicates a frame.

As the frame is read from tape, the ONES in the data

bits read are summed; the result is compared with the

parity bit read. If the parity bit written on tape matches

the comparison bit, then the frame is assumed to contain

the correct data. If the comparison bit does not match

the parity bit written on tape, then a parity error has

occurred.

Lateral parity checks are designed to locate the loss

or addition of one bit of data in a frame. They are one

of the most common fault indications encountered by

technicians working on magnetic tape devices. Parity

errors can result from a variety of mechanical,

electrical, and environmental problems.

9-9