continued increase of speed to normal increases the

centrifugal force developed by the rotating flyweights.

However, this increase of speed to normal does not

cause the flyweights to lift the pilot valve plunger above

center. Oil leakage through the needle valve orifice

equalizes the pressure above and below the

compensation land. This is at a rate proportional to the

return of the engine speed to normal. Then, as the

centrifugal force increases, the compensating force

decreases.

With the pressures above and below the

compensation land equalized, the buffer springs return

the buffer piston to its normal centered position.

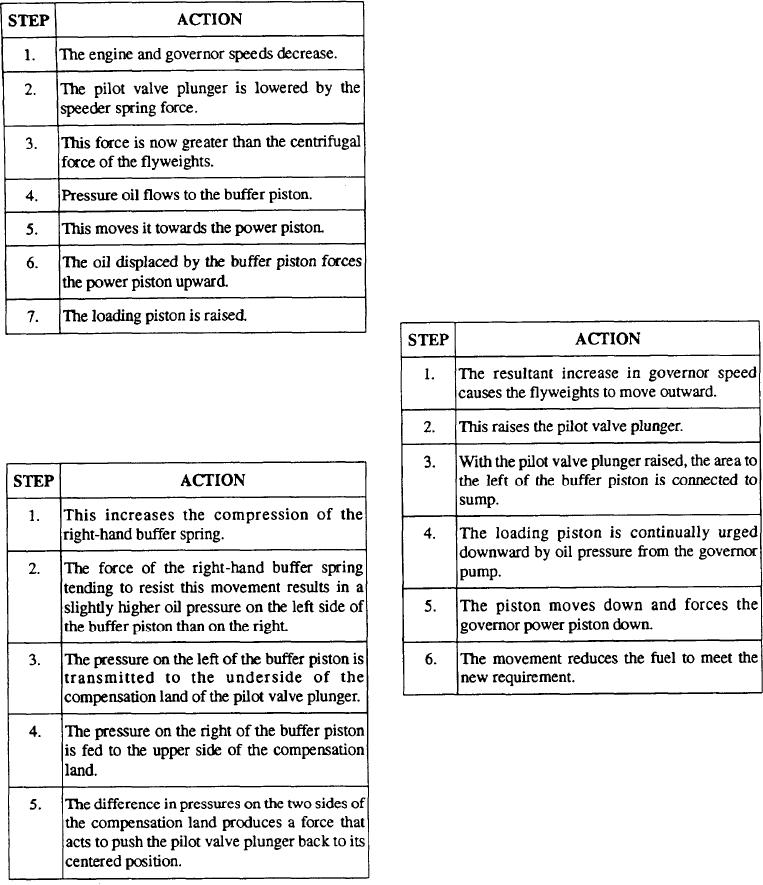

When engine load decreases, the following actions

occur:

The terminal shaft is then rotated in the direction to

provide the additional fuel needed for the new load.

The movement of the buffer piston towards the

power piston partially relieves the compression of the

left-hand buffer spring.

Again, differential pressure across the

compensation land helps to recenter the pilot valve

plunger.

The speed at which the governor controls the engine

is determined by the loading or compression of the

speeder spring. This spring opposes the centrifugal force

of the flyweights. The standard EGB-2P has a

speed-adjusting screw in the top cover, as shown in

figure 9-13.

When the terminal shaft has rotated far enough to

Speed Droop

satisfy the new fuel requirement, the pilot valve

recenters. This is caused by the differential force on the

Speed droop is used in governors to divide and

compensation land plus the centrifugal force of the

rotating flyweights. This happens even though the

balance load between engines or turbines driving the

same common load or driving generators paralleled in

engine speed has not returned complete] y to normal.

an electrical system. Speed droop is defined as the

Power piston and terminal shaft movement stops. The

9-19