The air brake can be set or released.

Function Control

The air clutch can be engaged or disengaged

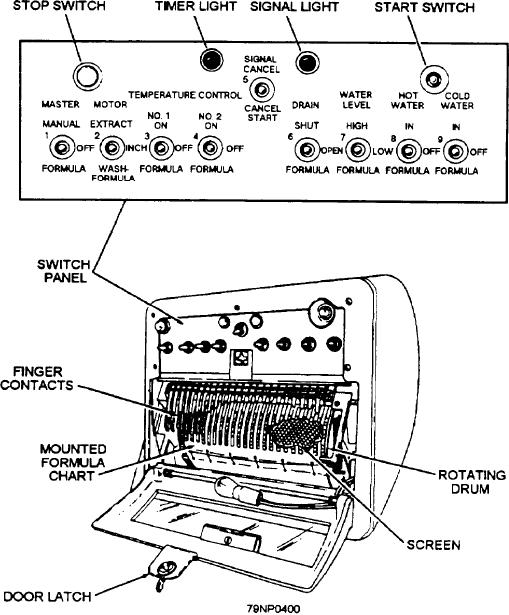

The automatic control timer (fig. 5-52) is the

The proper drive motor can be energized or

function control system for the washer-extractor.

Command and control signals are routed by finger

de-energized

contacts and/or switches in the control timer to sequence

The chart motor can advance the formula chart

functions and cycles within an operation during formula

(formula mode).

or manual mode.

The washer balance system can operate.

FORMULA MODE.-- A programmed formula

The washer door can be opened.

chart (fig. 5-53) is mounted on the rotating drum/copper

screen inside the control timer. During the formula

COMMAND CIRCUITRY.-- The 24-volt ac

mode, the drum rotates and finger contacts press against

command circuit generates command signals through

the chart. As a finger contact passes over a slot in the

the action of finger contacts and/or toggle switches. The

chart, it touches the copper screen. This completes an

command signals are routed throughout the washer to

electrical circuit and generates a command signal. Each

finger contact controls a different command signal. The

and solenoid valves sequence and control the duration

chart can control the wash operation by programming

of functions and/or cycles during a wash operation.

the time and duration of finger contact on the screen.

Figure 5-52.--A typical automatic control timer.

5-70