mechanically operates an electrical limit switch. This

lowering if the elevator with the arms open and unloaded

action automatically energizes the carriage return

or with the arms closed and loaded Emergency circuits

solenoid valve (fig. 5-36, view B) and allows the

bypass the normal control switches to provide a built-in

hydraulic fluid within the carriage return cylinder to

safety for emergency operation. They should never be

bleed off into the reservoir (fig. 5-36, view A). As the

used unless an emergency arises.

trolley moves all the way into the receiving head, the

ARMS ROTATION CONTROL SYSTEM.--

meeting carriage is pushed back into the INDEXED

The arms rotation control system controls the opening

position and the cylinder is collapsed. When the

and closing of the elevator arms for both normal and

meeting carriage solenoid valve is de-energized, the

emergency operations. The arms system consists of an

supply port to the cylinder is open, and hydraulic

electric motor (fig. 5-34), a speed reduction gearbox,

pressure pushes the meeting carriage into the

and a cross-shaft, worm gear mechanism. The

RECEIVED position. Upon trolley release, the

1 1/2-horsepower electric motor is bidirectional and is

jackknife and limit switch also return to their normal

watertight. It operates on 440-volt ac, three-phase,

operating positions.

60-hertz power at 1,800 rpm. The components, as a unit

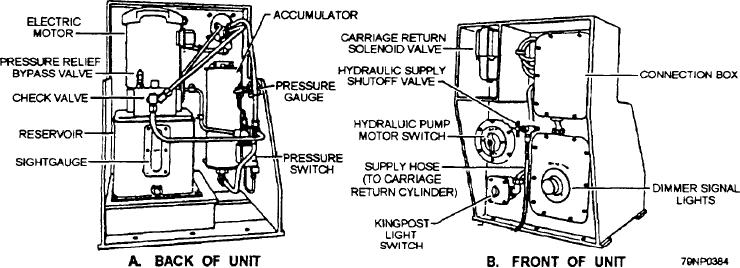

An electric motor mounted vertically on top of the

and with the necessary control circuitry, function to

reservoir (fig. 5-36, view A) operates a positive

open and close the arms of the elevator.

displacement gear type of hydraulic pump located inside

MEETING

CARRIAGE

CONTROL

the reservoir, The motor is a three-phase, 440-volt ac,

SYSTEM.-- The meeting carriage (fig. 5-34) receives

60-hertz, waterproof motor with a rating of 1 1/2

and cushions the incoming missile with the trolley

horsepower at 3,600 rpm. Operation of the hydraulic

catcher and jackknife units. The meeting carriage is

pump motor is automatic and maintains the hydraulic

pushed back horizontal y about 20 inches, moving from

fluid supply pressure at about 1,000 psi. During

the fully extended RECEIVED position to the fully

operation, whenever the supply pressure within the

compressed INDEXED position. The carriage is held

accumulator is below 950 psi, the oil pressure switch

in the INDEXED position by the trolley, which is

(fig. 5-36, view A) will close electrical contacts and start

retained by the trolley latch When the trolley latch is

the pump motor operating. As the pressure inside the

released the trolley is pulled from the receiving head.

accumulator reaches 1,000 psi, the oil pressure switch

Hydraulic pressure is automatically supplied to the

electrical contacts open and stop the motor. The console

carriage return cylinder, which extends the cylinder and

operator can override the automatic controls at anytime.

moves the meeting carriage to the RECEIVED position.

TROLLEY LATCH RELEASE.-- The trolley

During operation when the trolley enters the

latch (fig. 5-34) consists primarily of a latch pin and

receiving head, the jackknife folds back and

trunnion assembly, a locking arm, a solenoid, two limit

Figure 5-36.--Carriage return hydraulic power unit: A. Back of unit: B. Front of unit.

5-54