When the operating voltage drops below its minimum

to convert the electrical power to high voltage 10,000

requirement the lamp will go out.

volts dc. As you read this section refer to figure 5-19.

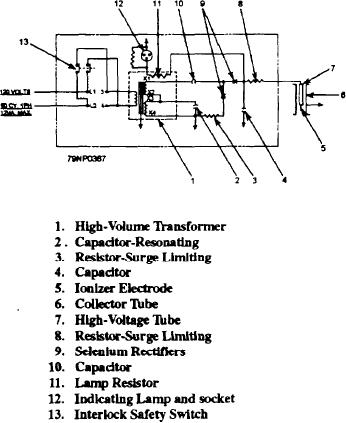

The access cover safety switch (13) is an interlock.

The power pack and circuitry are shown in figure

With the cover removes the contacts are open and

5-19. The circuit is a half-wave voltage doubler,

de-energize the primary of the power supply.

consisting of a high-voltage transformer (1), two

selenium rectifiers (9), and two capacitors (4 and 10).

The components of the precipitator are the ionizer

The power supply assembly is the self-regulating type

electrode (5) and the electrode chuck and high-voltage

commonly known as a constant-voltage transformer.

tube (7). The assembly is held inside the collector tube

The resonating winding (X3-X4) connected to the

(6) by an insulator. The insulator also serves to

resonatiing capacitor (2) serves to hold the power supply

electrically insulate the high-voltage assembly.

voltage at a constant level when the primary input

voltage varies. The resonating circuit is designed to

SUMMARY

help limit the output power.

The high voltage from the power supply is

The vent fog precipitator is a simple, rugged,

connected to a surge limiting resistor (8), which limits

essential piece of equipment. By following posted

the current of an arc that might occur and provides

maintenance procedures, it will remain a reliable,

protection for the capacitors.

operational piece of equipment.

The negative output of the power supply is

connected to ground through a surge limiting resistor

PROPULSION SHAFT

(3). This resistor limits the feedback current due to an

TORSIONOMETER

arc. It provides additional protection to the capacitors

through the ground terminal of the precipitator. The

The propulsion shaft torsionometer is a device used

proper operation is indicated by a lamp (12) that is

to measure the torque and (optionally) the rpm of a

connected to a resistor (11). A portion of the supply

ship's rotating propulsion shaft accurately. Of the types

output voltage is used for the neon indicating lamp.

available in the fleet, the basic principles are the same.

By accurately measuring the torsional twisting of a

ship's propulsion shaft, you can calculate the load

(torque) on the ship's main engine. Using this figure,

the load on the shaft can be calculated into shaft

DESCRIPTION

Through the use of various sensors and components,

the shaft torsionometer detects the slight twisting and

(optionally) the rpm of the ship's propulsion shaft. Then

the torsionometer produces a proportional signal and

uses the signal to drive appropriate indicators located

near the ship's engineering console or on the bridge.

Shaft horsepower readings may also be displayed at

various remote locations, such as the pilothouse or the

chief engineer's office, using repeaters or remote

displays.

The optional rpm system uses an rpm probe to

receive signals from a shaft mounted assembly. The

signals are then processed by the rpm conditioner and

sent through shipboard cables to the appropriate

Figure 5-19.--Vent fog precipitator wiring diagram.

indicators.

5-32