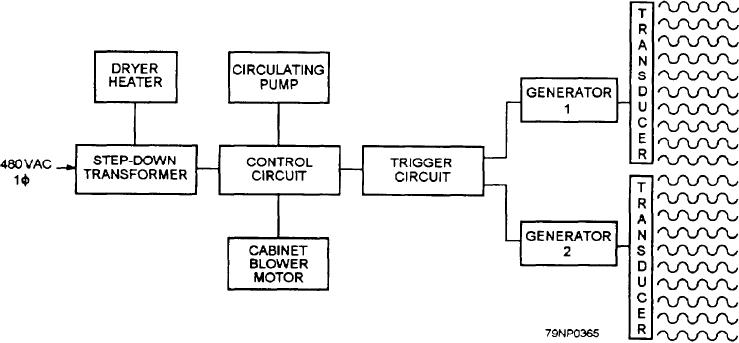

Vibrations are generated in the ultrasonic cleaner

dirt accumulations and the air filters in the generator

(fig. 5-17) by transducers. These transducers are

compartment door should be cleaned or replaced

welded to plates, called diaphragms. When the

periodical y according to PMS requirements. The

generator fans and cleaner unit blower should be oiled

transducers arc energized, they produce extremely small

vibrations in the plates, 1 or 2 thousandths of an inch

once a year and the water pump should be oiled every 6

months.

(0.001 to 0.002 inch) but with strong accelerating forces.

As the plates vibrate, they cause whatever medium they

are suspended in to assume a similar frequency and

SUMMARY

transmit that frequency throughout the vessel. The

plates are, in effect, a Hi-Fi speaker operating at one

The ultrasonic cleaner is one of the most essential

frequency.

machines on board when it comes to conducting repairs

to other pieces of machinery. Its ability to clean parts

When the medium through which the waves are

and some metallic ventilation filters makes it mandatory

transmitted is a liquid, there is good transmission and

that preventive maintenance procedures be strictly

very little loss of strength since all liquids are relatively

followed to ensure it stays operational.

incompressible. The physical shock of the vibrations on

the item being cleaned cause a "scrubbing" action much

better than a brush because the size of the sound waves

ELECTROSTATIC VENT FOG

allows for cleaning of minute holes and crevices that

PRECIPITATOR

would be impossible for a brush.

The electrostatic vent fog precipitator (fig. 5-18) is

mounted in the lube oil system of reduction gears for

MAINTENANCE

main engines and generators. The purpose of the vent

fog precipitator is to remove entrained oil mist from the

The ultrasonic cleaner is extremely rugged and

vented air of the reduction gears before it is discharged

requires little maintenance other than cleaning and

oiling. The components should be kept free of dust and

into the engine mom or space.

Figure 5-17.--Block diagram of ultrasonic cleaner.

5-30