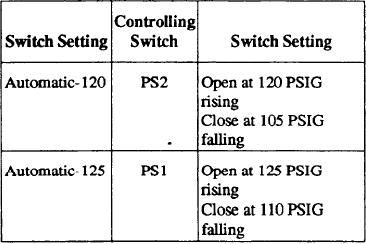

Table 5-2.--Automatic Mode Settings of a Typical LP Air

The high air temperature switch (TS) closing

The high injection water level switch (LS1)

closing

The low oil pressure switch (PS4) closing after

the timing relay (6TR) has timed closed

The low injection water pressure switch (PS3)

closing after the timing relay (6TR) has timed

closed

The low injection water level switch (LS2)

closing

The high condensate sump water level switch

(LS6) closing

Turning the selector switch (3SEL) to the ON

The high dew point temperature switch (HDP) in

position initiates the following sequence:

the dehydrator closing after the timing relay

NOTE: The following operating sequence

(4TR) has timed closed

describes control functions with the selector switch

(1SEL) in the AUTOMATIC-125 PSIG position under

The undervoltage relay (UV) contacts opening

control of the pressure switch (PS1). With the selector

The motor overload (OL) contacts opening

switch in the AUTOMATIC- 120 PSIG position, control

functions are the same but are under the control of the

A fuse (1FU, 2FU, 3FU, or 4FU) failing

pressure switch (PS2).

The operator turning the selector switch (3SEL)

1. The control relay (5CR) in the low-voltage

to the OFF position

circuit is energized. The 5CR contacts in the

The operator pressing the remote EMER STOP

high-voltage circuit close to energize the undervoltage

relay (W). The white ENABLE RUNNING light

push button, provied the selector switch (2SEL)

(WIL) is-lit on the controller door.

is in the REMOTE position

2. The UV interlocks close to provide power to

NOTE: If an automatic safety shutdown occurs, the

other parts of the control system and energize the remote

remote SAFETY ALARM will be energized by the

ENABLE RUNNING light.

control relay (2CR). If a manual shutdown occurs, the

3. The timing relay (1TR) and control relay (1CR)

remote EMER STOP lamp will be lit. If any shutdown

are energized and the following actions occur

occurs in the MANUAL operating mode, both remote

simultaneously:

and local ENABLE RUNNING and MOTOR

One set of timed-to-open (off-delay) relay 1TR

RUNNING lamps will be extinguished

contacts close to energize the motor contactor (M),

which closes the M contacts in the motor wiring leads

to start the motor. The M contacts in the low-voltage

Automatic Operation

circuit also close to energize the TOTAL RUNNING

TIME meter (ETM) and the local and remote MOTOR

Figure 5-9 is a schematic diagram of the air

RUNNING lights.

compressor control system. Please follow figure 5-9 as

A second set of 1TR contacts closes at the same

the step-by-step operation of the automatic operation is

time as the control relay (1CR). Normally closed (NC)

discussed. The controller is placed in the automatic

contacts open in the circuit to the unloader solenoid

mode of operation by the selector switch (1SEL) (table

valve (SV4) to prevent operation of the valve. Other

5-2) being placed in either the AUTOMATIC-125 PSIG

1CR normally open (NO) contacts close to energize the

LOADED RUNNING TIME meter (LHM).

or AUTOMATIC-120 PSIG position.

5-17