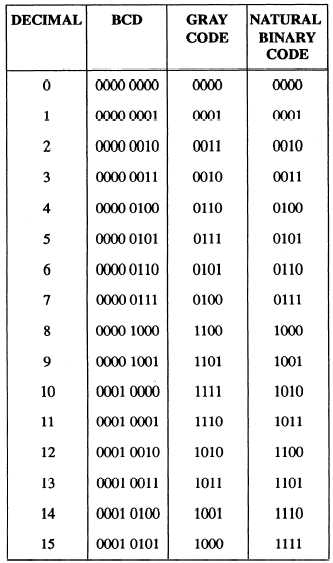

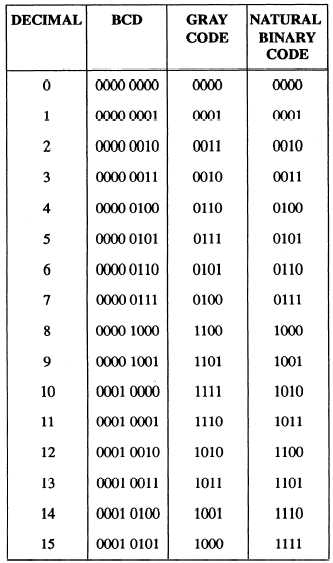

Table 13-1.—Comparison of Binary-Coded Decimal (BCD),

Gray Code, and Natural Binary Code

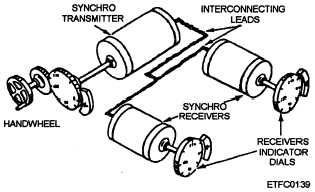

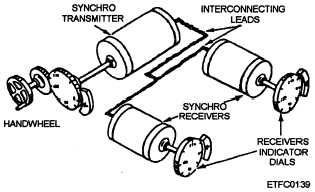

Synchro Systems

The term synchro is an abbreviation of the word

synchronous. It is the name given to a variety of rotary,

electromechanical, position sensing devices. Synchro

signals are used to transmit the angular position (0 to

360 degrees) of a rotor shaft in a synchro transmitter.

When the signals are applied to one or more synchro

receivers, the rotor shaft-in each receiver is positioned

to match the transmitter’s shaft position (figure 13-4).

In this example, the receiver shaft in turn drives an

indicator dial to display the transmitted information.

The combination of synchro transmitter and

receivers is called a synchro system. There are two

major classifications of synchro systems: torque

systems and control systems.

Figure 13-4.—Torque synchro system transmitter and

receivers.

Torque systems provide torque or turning force to

drive light loads such as indicator dials, pointers, or

other mechanical outputs.

Control synchro systems provide an electrical

output used to control the power that performs

mechanical work. The control synchro normally feeds

a control transformer, not a control receiver. The

control transformer output is fed to devices such as a

servo system to control larger systems and devices.

The synchro signals converted by CDS equipment

may be either control synchro signals or torque synchro

signals; however, control synchro signals are preferred

because they are generally more accurate than torque

synchro signals.

OPERATING VOLTAGES AND FRE-

QUENCIES.— Most shipboard synchro systems

operate on a supply voltage of 115 volts ac at a

frequency of 60 or 400 Hz. Synchros operating at 115

volts 400 Hz are generally more accurate than the 60-Hz

synchros. Most newer weapon systems use 400-Hz

synchros exclusively.

SINGLE-SPEED, MULTISPEED, AND

DUAL-SPEED SYNCHRO SYSTEMS.— The

accuracy of the data to be transmitted is a factor in any

synchro system.

If the data covers a wide range of

values, then the basic synchro system is unable to detect

small changes in the data. When this happens, the

accuracy of the system decreases. Multispeed synchro

systems were developed to correct this deficiency.

Multispeed synchro systems use more than one

speed of data transmission. The speed of data

transmission is the number of times the synchro

transmitter rotor must turn 360 degrees to transmit a full

range of values. In a 1-speed system, one rotation of

the transmitter rotor covers the full range of values. The

13-5