l Magnetic tape is less prone to damage than other

forms of magnetic storage media

PHYSICAL PROPERTIES OF MAGNETIC

TAPE

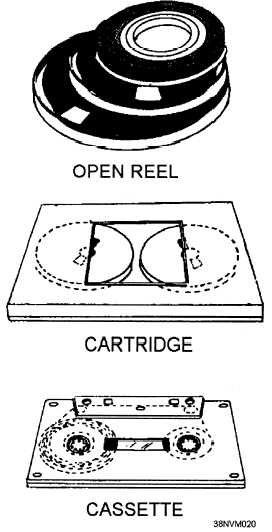

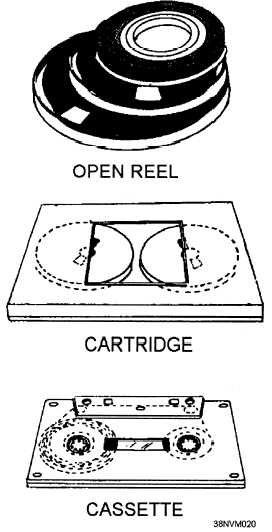

Magnetic tape comes in a variety of widths and

lengths. It maybe contained in one of three categories

of storage media: industry standard open reels,

cartridges, or cassettes. Figure 9-1 shows the different

categories of magnetic tape media.

MAGNETIC TAPE CONSTRUCTION

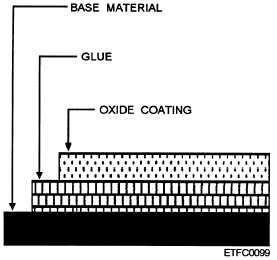

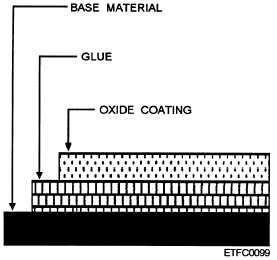

Three basic materials are used to make magnetic

tape. They are:

l The base material

l A coating of magnetic oxide particles

Figure 9-1.—Magnetic tape reels, cartridges, and cassettes.

l A glue that binds the oxide particles to the base

material

Figure 9-2 illustrates the basic construction of a

magnetic tape.

Base Material

The base material for magnetic tape is made of

either plastic or metal. Plastic tape is more common

because it is very flexible, resists mildew and fungus,

and is very stable at high temperatures and humidity.

Oxide Coating

Oxide particles that can be easily magnetized

(ferrous) are coated onto the base material. The most

common oxide materials are gamma ferric oxide and

chromium dioxide. It is very important that the oxide

particles are uniform in size and shape. If they are not,

the tape’s surface will be abrasive and might damage

the tape unit’s head.

Glue

The glue used to bond the oxide to the base is

usually an organic resin. It must be strong enough to

hold the oxide in place, yet flexible enough not to peel

or crack.

MAGNETIC TAPE HANDLING

PROCEDURES

Magnetic tape handling procedures include the

storage, handling, maintenance, and control of tapes.

Figure 9-2.—Magnetic tape construction.

9-2