The print drum is an aluminum cylinder coated with

a photosensitive material. This material is highly

conductive when exposed to light and has low

conductance in darkness.

The laser source is from a small laser diode that

generates a single wavelength light in bursts of a

millionth of a second or less. The laser is focused on the

drum and illuminates areas of the drum to form

characters.

To start a print cycle, the drum is first cleaned, both

physically and electronically. The cleaning blade wipes

any residual toner from the drum. The erase lamps are

turned on and neutralize any charge that maybe on the

drum. A negative charge of approximately -600V is

applied to the entire drum surface by the primary corona

wire.

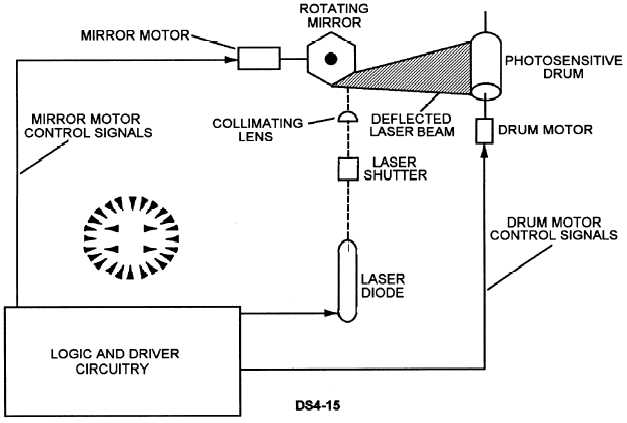

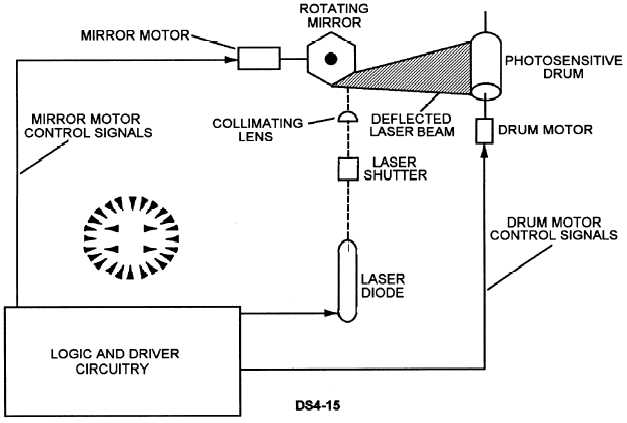

The laser beam is applied to the drum, causing the

exposed areas of the drum to become positively

charged. Figure 12-14 shows the basic laser imaging

and scanning mechanisms. The laser beam is directed

through a shutter to a rotating hexagonal mirror. As the

mirror rotates, the area of the drum that the reflected

beam strikes changes. This is the horizontal scan of the

laser. To properly charge the drum, the laser shutter

controls when the laser beam will actually strike the

drum. When one horizontal scan is completed, the

drum is advanced one dot space and the process is

repeated. The characters are actually formed through a

series of dots, much like a dot matrix printer.

As the drum is rotated, it passes by the toner

reservoir. The toner consists of a very fine powder of

metal, dyes, and plastic particles that are easily attracted

by static electricity. As the exposed drum passes by the

toner, the positively charged areas of the drum attract

the toner while the other areas remain clean.

While all this is happening, the paper-feed section

of the printer picks one piece of paper from the tray.

The paper is lined up with the registration rollers and is

ready to be printed on. The paper is passed over the

transfer corona at the same time the charged area of the

drum is over the paper path. The transfer corona

charges the paper at a higher charge than the drum,

pulling the toner from the drum to the paper. The paper

never actually contacts the drum.

The image is now on the paper but it is not

permanent. The paper is fed through the fusing rollers.

The fusing rollers apply heat and pressure to the paper,

causing the toner to melt and permanently bind to the

Figure 12-14.—A laser imaging system.

12-12