RUBBER GLOVES

DECK MATTING

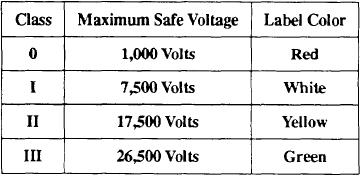

There are four classes of rubber insulating gloves.

An insulating deck covering prevents electric shock

The primary feature being the wall thickness of the

to anyone who may touch bare, energized, ungrounded

gloves and their maximum safe voltage, which is

circuits. You must use approved rubber floor matting in

identified by a color label on the glove sleeve. Use only

electrical and electronic spaces to eliminate accidents

rubber insulating gloves marked with a color label.

and afford maximum protection from electric shock.

Table 1-1 contains the maximum safe use voltage and

NSTM, chapter 634, table 634-1, gives approved deck

label colors for insulating gloves approved for Navy use.

coverings for every space in your ship. Accident

Before using rubber gloves, carefully inspect them

investigations often show that the floors around

for damage or deterioration. To inspect robber gloves

electrical and electronic equipment had been covered

for tears, snags, punctures, or leaks that are not obvious,

only with general-purpose black rubber matting. The

hold the glove downward, grasp the glove cuff, and flip

electrical characteristics of this type of matting do not

the glove upward to trap air inside the glove. Roll or

provide adequate insulation to protect against electric

fold the cuff to seal the trapped air inside. Then squeeze

the inflated glove and inspect it for damage. For

shock. There are various types of electrical grade mats

additional information on rubber gloves, refer to Naval

or sheet coverings conforming to Military Specification

Ships' Technical Manual, chapter 300.

Mil-M-15562 that meet the requirements.

To ensure that the matting is completely safe, you

ELECTRICAL FIRES

must promptly remove from the matting surfaces all

When at sea, fire aboard a Navy vessel is more fatal

foreign substances that could contaminate or impair its

and damaging to both personnel and the ship itself than

dielectric properties.

damage from battle. The time to learn this is as soon as

Th dielectric properties of matting can be impaired

you report aboard. The Navy requires that all hands must

be damage control qualified within 6 months after

or destroyed by oil, imbedded metal chips, cracks, holes,

reporting aboard. You must learn the types of

or other defects. If the matting is defective, cover the

fire-fighting equipment, their location, and their

affected area with a new piece of matting. Cementing

operating procedures. It is too late after the fire has

the matting to the deck is not required, but is strongly

started.

recommended This prevents removal of the mat for

inspection and cleaning, which would leave the area

FIGHTING AN ELECTRICAL FIRE

unprotected. If the mat is not cemented, stencil an

outline of the proposed mat on the deck. Inside the mat

Use the following general procedures for fighting

outline, stencil " E L E C T R I C - G R A D E M A T

an electrical fire:

REQUIRED WITHIN MARKED LINES." Use

1. Promptly de-energize the circuit or equipment

3/4-inch or larger letters.

affected. Shift the operation to a standby circuit

or equipment, if possible.

Electrical insulating deck covering should be

installed so there are no seams within 3 feet of an

2. Sound an alarm according to station regulations

electrical hazard. Where this is not possible,

or the ship's fire bill. When ashore, inform the

thermoplastic deck coverings, such as vinyl sheet

Table 1-1.--Rubber Gloves

manufactured by Lonseal, Inc., should be fused

chemically, heat welded, or heat fused with a special hot

air gun. With rubber deck coverings, fusing with heat

is not possible. A 3- or 4-inch wide strip of #51

Scotchrap 20-mil thick Polyvinyl Chloride (PVC) tape

(manufactured by Minnesota Mining and

Manufacturing Company) should be installed beneath

the seam. You also may use a 1-foot wide strip of

electrical grade deck covering under either rubber- or

vinyl-type coverings (instead of heat welding vinyl).

1-16