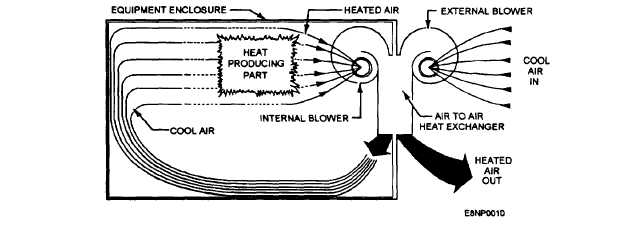

Figure 1-3.—Forced-air coding.

FORCED-AIR COOLING

The increase the cooling effect over that provided by

convection cooling, forced-air cooling (fig. 1-3) uses a

blower to provide air movement instead of the natural

convection currents. Cool air is drawn into the

equipment enclosure and flows past the heat producing

part, picking up the heat. The air is then exhausted out

of the equipment. An air filter is provided at the air inlet

to remove dust and dirt that otherwise would settle on

the internal parts of the equipment. The air filter must

be kept clean according to the equipment’s maintenance

requirements. This will ensure maximum air movement

and cooling.

In some equipment, a honeycomb rf interference

filter is installed on both input and outlet to prevent stray

rf from entering or leaving the equipment cabinet. This

filter can also collect dirt that can reduce the airflow.

Failure of a bearing in the blower motor is not an

uncommon problem. A replacement of both blower

motor bearings or blower assembly is warranted at the

first sign of abnormal operation, such as excessive noise

or vibration. It is better to replace the bearings than to

risk damage to the equipment that the blower motor is

designed to protect.

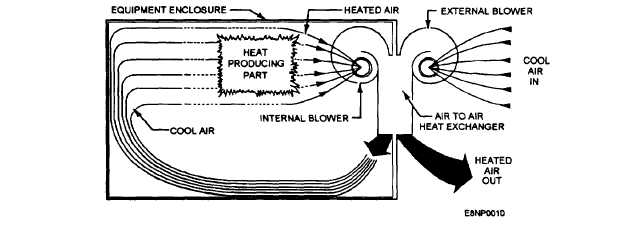

AIR-TO-AIR COOLING

Some units of electronic equipment are

hermetically sealed to prevent the entrance of moisture.

For equipment of this type, an air-to-air heat exchanger

(fig. 14) is used to prevent the air inside the equipment

enclosure from mixing with the outside air and still

allow cooling to take place. Air moving past the heat

producing part absorbs heat and is forced through a heat

exchanger by an internal blower. The heat in the internal

air is absorbed by the heat exchanger. The cooled

internal air is then returned to the equipment interior to

continue the cycle.

Figure 1-4.—Air-to-air cooling.

1-2